rubberduck

Seasoned Member

- Joined

- Mar 11, 2022

- Messages

- 2,467

- Location

- Arizona

- V-Series Cadillac(s)?

- 22 CT5V BW Shadow Metallic 6M

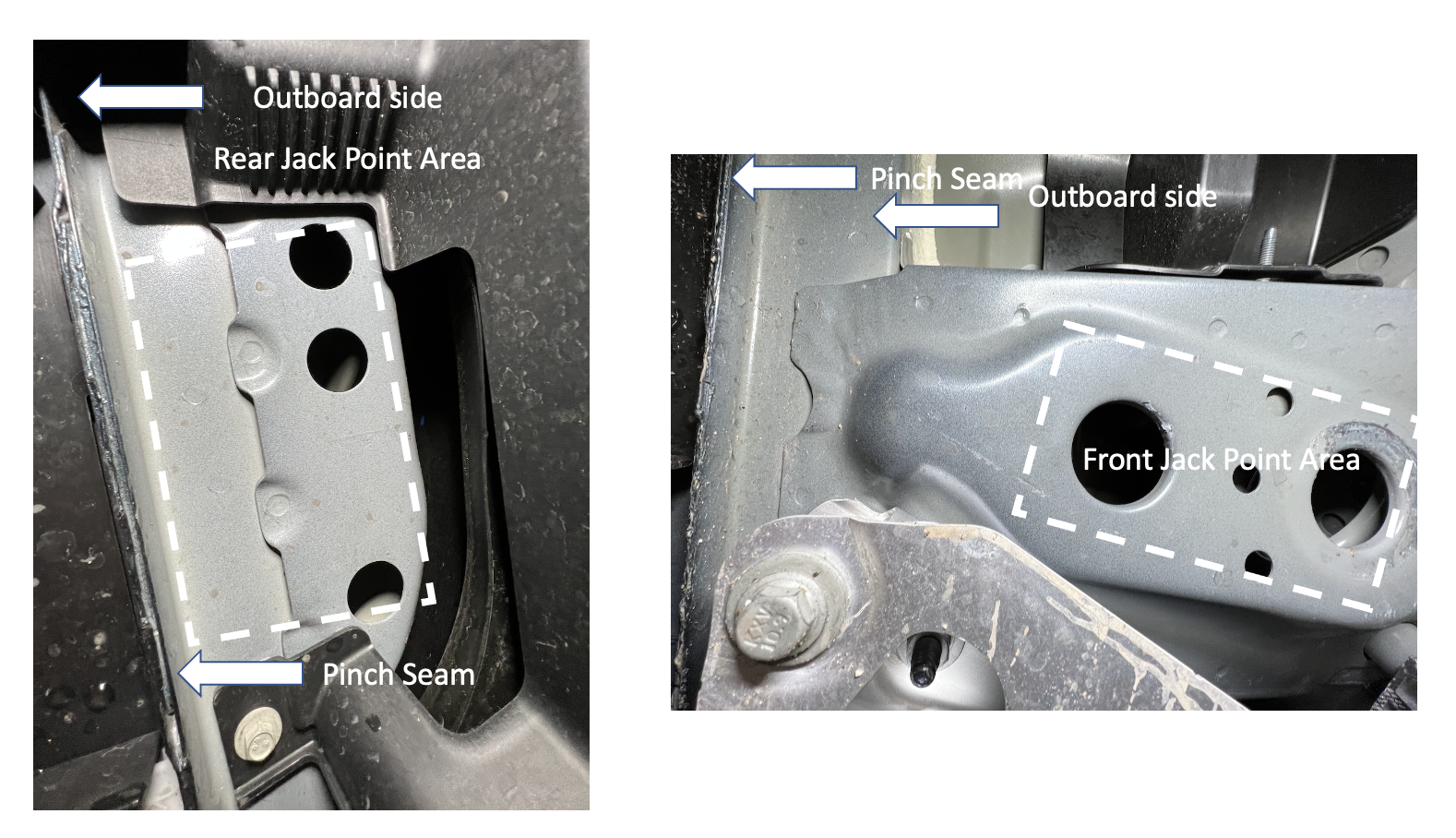

Got around to carefully taking a look at the jack points and noticed that on both the front and rear there are plastic pieces right underneath the the outboard side of the pinch seams. These would likely crack if one used this location with a jack pad/adapter. Not that it would be that big a deal if they cracked, but decided to go with the Quickjack blocks as they fit perfecting in the jack point areas. They are 4"x3"x3" (L x W x H) and the 3" height is a real plus in clearing the side rocker panels. Used Amazon points so it wasn't painful.

I looked into sourcing some polyurethane material from McMaster-Carr and it really wasn't much cheaper than buying the blocks premade and saves me from doing another small project.

I looked into sourcing some polyurethane material from McMaster-Carr and it really wasn't much cheaper than buying the blocks premade and saves me from doing another small project.

Last edited: