I don't have a blackwing yet, but my 56" ramps fit under my S2000 - I can't even get a low profile Harbor Freight aluminum racing jack under it without driving up on 2x4s first. Dimensions are on their website so you can measure before you buy, but I have to imagine the 56" would work and are cheaper and smaller to store than 67"Race Ramps are the best. 67" are ideal but you could get away with the 56" model. You can get them in one piece or two piece.

Speedway sells some bundles with wheel chocks.

Loading Products... | Speedway Motors, The Racing and Rodding Specialists

www.speedwaymotors.com

Welcome to the Cadillac V-Series Forums!

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Jacking up your Blackwing

- Thread starter Mbar

- Start date

raptor5244

Seasoned Member

- Joined

- Aug 7, 2022

- Messages

- 908

- Location

- Florida

- V-Series Cadillac(s)?

- 2022 CT4-V Blackwing - 46-381

Yeah. I think the approach angle on the 56” will be fine for the Blackwings. I went with the 67” since I had a C7 Grandsport at the time.I don't have a blackwing yet, but my 56" ramps fit under my S2000 - I can't even get a low profile Harbor Freight aluminum racing jack under it without driving up on 2x4s first. Dimensions are on their website so you can measure before you buy, but I have to imagine the 56" would work and are cheaper and smaller to store than 67"

Snowwolfe

Seasoned Member

I like the 67 inch Race Ramps. The really nice feature of these ramps is being able to remove the ramp portion behind the front wheels which improves the access for crawling under the car.

Lithoss

Seasoned Member

Funny timing.. woke up this morning to a text saying one of my tires was flat. Sure enough, back left is flat on my 4BW. I want to take it off and bring just the wheel/tire into the tire shop.. best place to jack and then stand the back left?

KatyTxCT5V

Seasoned Member

My 67” Race Ramps worked perfectly when I changed my oil. I’ve had them since 2016 and bought for my 16’ Z06. Easy to store and use on all my cars. Here’s my 22’ 5BW when I recently changed my oil. Don’t forget to chock your wheels as extra safety. I use the Race Ramps wheel chocks.I like the 67 inch Race Ramps. The really nice feature of these ramps is being able to remove the ramp portion behind the front wheels which improves the access for crawling under the car.

OldGoat

Seasoned Member

- Joined

- Jun 30, 2022

- Messages

- 643

- Location

- Central New Jersey

- V-Series Cadillac(s)?

- 2022 CT5V Blackwing

Epoxy floor paint? How old is it and how's it holding up.My 67” Race Ramps worked perfectly when I changed my oil. I’ve had them since 2016 and bought for my 16’ Z06. Easy to store and use on all my cars. Here’s my 22’ 5BW when I recently changed my oil. Don’t forget to chock your wheels as extra safety. I use the Race Ramps wheel chocks.

View attachment 18034

KatyTxCT5V

Seasoned Member

I had the home builder install when I bought the house new 6/2011. It’s held up ok, but under where the tires sit, just started pulling up. Don’t know if I should start scraping up and reapply or add tiles similar race deck type. I do like when I spill oil on occasion I can just wipe it up.Epoxy floor paint? How old is it and how's it holding up.

Jameson's Viggen

Seasoned Member

I cheaped out and had mine done in '17 when I put in a lift. I had the 3year warranty stuff done vs the 5yr and yeah, it cracked in places and doesn't look great. I'll do the Race tiles one day.Epoxy floor paint? How old is it and how's it holding up.

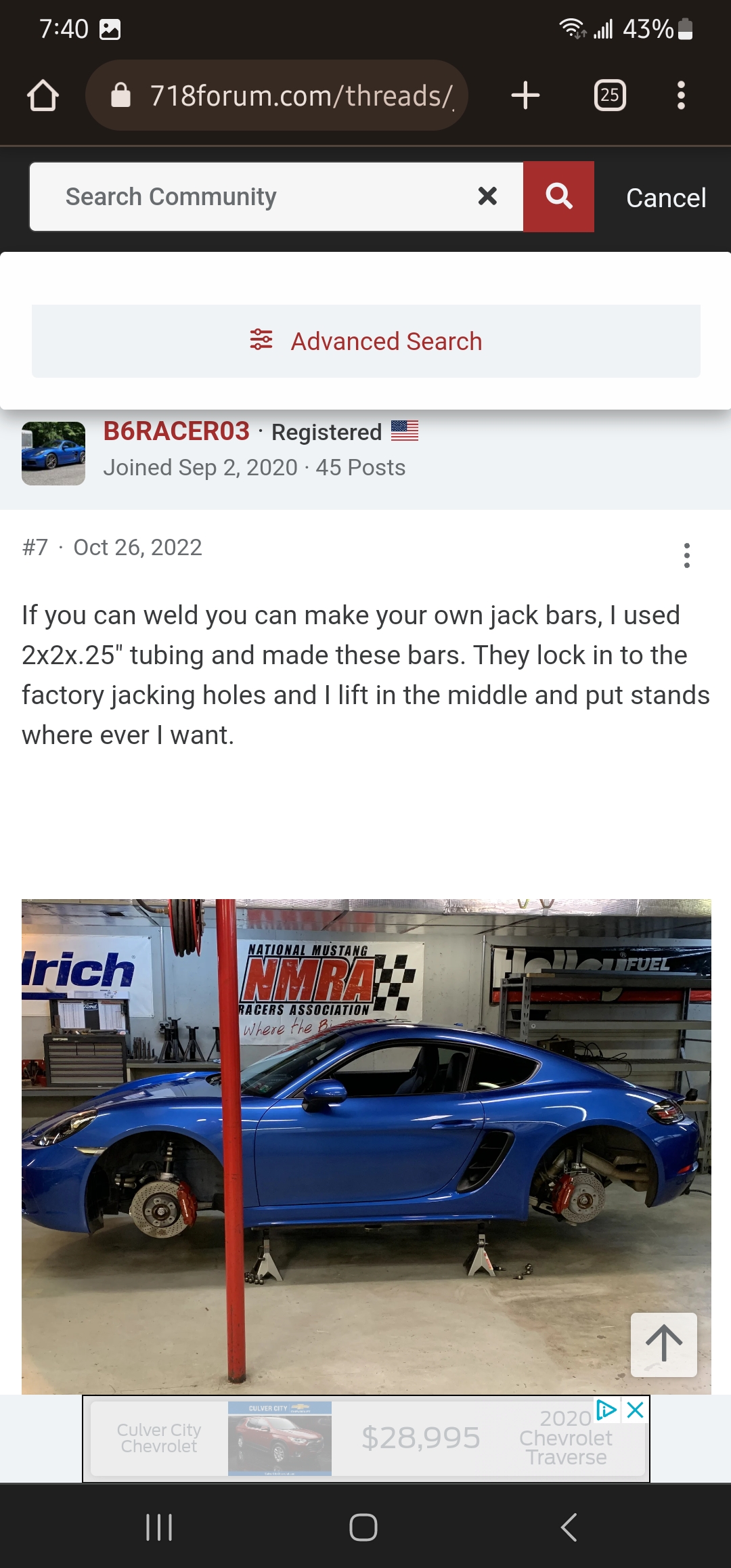

Correct me I'm wrong but unless you have a Quickjack or Jackpoint stands (which have been out of stock for years), you really have no way to jack up the car at the pinch weld and place a jack stand in the proper spot.

I saw this and thought it was brilliant...

I saw this and thought it was brilliant...

rubberduck

Seasoned Member

- Joined

- Mar 11, 2022

- Messages

- 2,467

- Location

- Arizona

- V-Series Cadillac(s)?

- 22 CT5V BW Shadow Metallic 6M

What about the Rennstand, those any good?Correct me I'm wrong but unless you have a Quickjack or Jackpoint stands (which have been out of stock for years), you really have no way to jack up the car at the pinch weld and place a jack stand in the proper spot.

Lithoss

Seasoned Member

What's the verdict on jacking the rear by lifting the differential? with rubber pad?

Fawkes

Member

The jacking information from the CT4 service manual says:

Frame Contact Lift:

The vehicle should be lifted so that the hoist pads and or lift arms do not contact the rocker panel molding. The hoist pad must be located in the designated area. In the front location, place the lift pads on the rocker outer panel weld flange. In the rear location, place the lift pads on the rocker outer panel rear cradle brace. Care should be taken to ensure the hoist pad is inside the rocker panel molding cut out area (notch) to prevent damage to the vehicle.

Front Lift Pads

View attachment 17802

When lifting the vehicle with a frame-contact lift, position the pad as close as possible to the rocker molding cutout.

Rear Lift Pads

View attachment 17803

When lifting the vehicle with a frame-contact lift, cover the inner and outer edges of the rear suspension bracket (arrow). Use the cutout in the rocker molding to correctly position the pad for/aft. If you need to remove the rear suspension bracket, place a jack stand under area X. Raise the jack stand high enough to free the hoist pad from the rear suspension bracket for service.

Vehicle Jacking:

Caution: When you are jacking the vehicle at the front locations, be certain that the jack or the jack lift pad does not contact the front fascia, front fascia air dam, or the front fenders. If such contact occurs, vehicle damage may result. When jacking at selected front locations additional clearance may be required for the jacking points.

Note: When you are lifting a vehicle with a service jack, block the wheels at the opposite end from which you are lifting. Use jack stands to provide additional support.

Front of vehicle

View attachment 17806

When using a service jack under the front of the vehicle use one of the following locations:

Place the service jack pad in the same location as shown for the front lift pads or on the front center jack pad shown.

Rear of Vehicle

Note: Place jackstands ONLY under strong and stable vehicle structures.

Place the service jack pad in the same location as shown for the rear lift pads.

So I'm quickly closing on my 1500 mile oil change and trying to understand this thread. Thanks for sharing the above pictures but like others have said they're pretty weak.. Silly GM..

To confirm, for 4BW, the front jack location:

View attachment 18014

And rear:

View attachment 18015

If so... What a pain!

The front center location picture.... It looks nothing like mine does so I think I'm going to have to jack the sides to crawl under and really take a better look....

CT4, CT4-V or CT4-B Blackwing Lift Points

From the CT4 Service Manual that was shown by @Dirkbg above, I tested those locations using a low profile jack + three hockey pucks stacked (each 3"x1" WxH) to lift the car for some wheel detailing work. I used the pucks as that were the only pads immediately available for me but a better option would be the Quickjack Pinch-Weld Blocks that @Jameson's Viggen noted he purchased for lifting his 4BW. I measured the front molding opening at the pinch weld and these Blocks would fit nicely.

For the FRONT, I used the pinch weld as noted in the instructions: "In the front location, place the lift pads on the rocker outer panel weld flange."

For the REAR, I used the rear cradle brace per instructions, diagram, and pics.

Lithoss

Seasoned Member

I had Cadillac Sewell roadside assistance come take care of my tire today since I had the Tire&Wheel warranty anyway. They're great, if anyone was wondering. He even showed up in an Escalade with all his tools/equipment in the back.

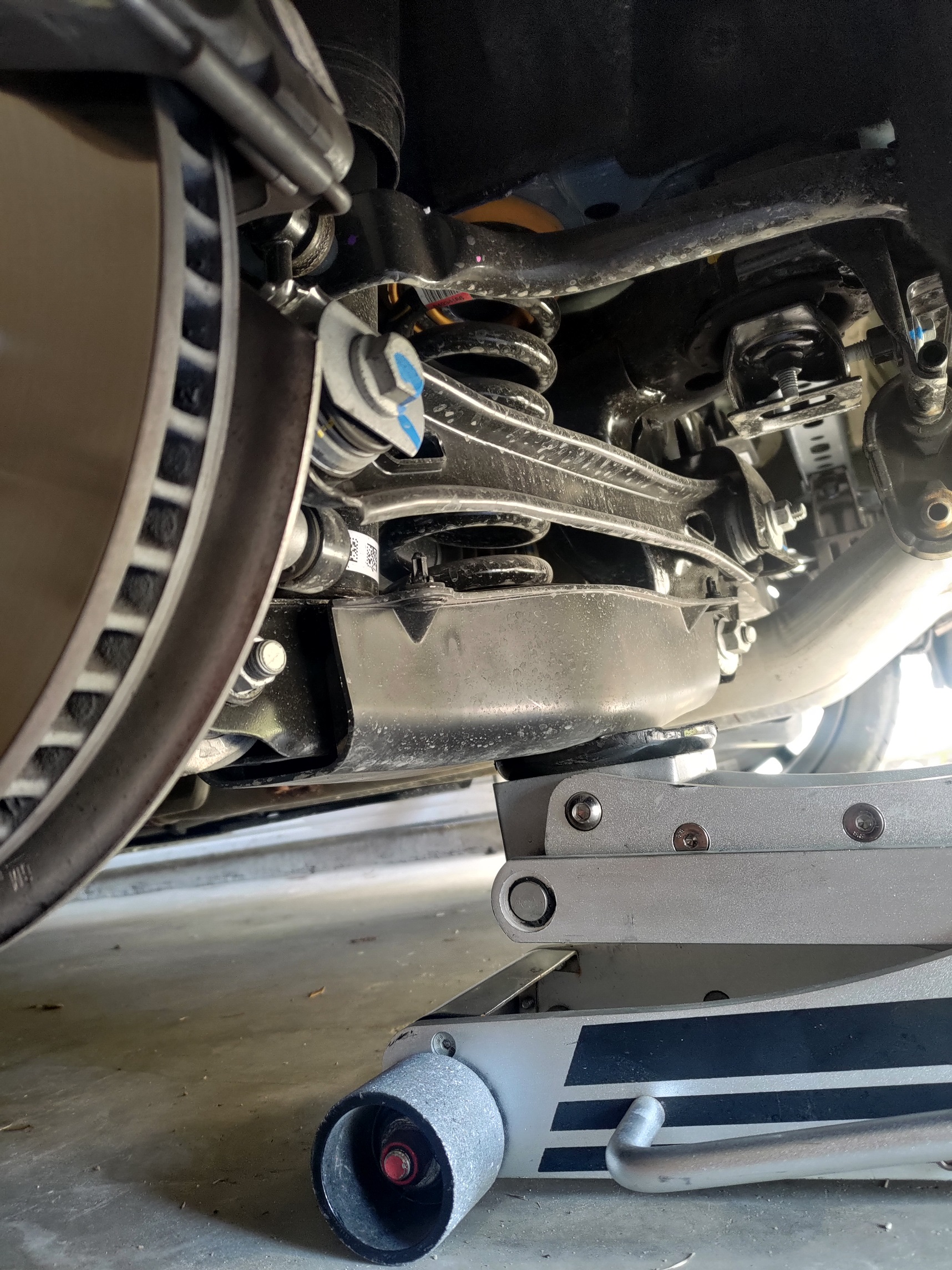

But, on topic... he jacked my rear left from here:

Also, stupid screw:

But, on topic... he jacked my rear left from here:

Also, stupid screw:

MatthewAMEL

Seasoned Member

He jacked up the car using the plastic lower control arm cover?I had Cadillac Sewell roadside assistance come take care of my tire today since I had the Tire&Wheel warranty anyway. They're great, if anyone was wondering. He even showed up in an Escalade with all his tools/equipment in the back.

But, on topic... he jacked my rear left from here:View attachment 18095

Also, stupid screw:

View attachment 18096

raptor5244

Seasoned Member

- Joined

- Aug 7, 2022

- Messages

- 908

- Location

- Florida

- V-Series Cadillac(s)?

- 2022 CT4-V Blackwing - 46-381

Wondering the same thing? That seems like the worst place to jack the car unless you want to crack the plastic.He jacked up the car using the plastic lower control arm cover?

Lithoss

Seasoned Member

Yep. No damage to the plastic that I can see. I assume the actual arm is right under it with very little gap. I'm not saying it's the best but it worked.

Dirkbg

Seasoned Member

You got screwed.I had Cadillac Sewell roadside assistance come take care of my tire today since I had the Tire&Wheel warranty anyway. They're great, if anyone was wondering. He even showed up in an Escalade with all his tools/equipment in the back.

But, on topic... he jacked my rear left from here:View attachment 18095

Also, stupid screw:

View attachment 18096

SonnyAK

Seasoned Member

Just installed the ZL1Addons lift points on my 5BW yesterday and decided to trim the plastic a bit from the inside of the rocker panel trim and inset them. I initially installed them over the plastic but didn’t like how it slightly flexed the rocker. Trimming was very easy using a cutting bit on my dremmel.

JTugwell

Seasoned Member

I could not get that quickjack pinch weld block to fit on the rear jacking point of the CT-4 BW. They also make a pinch weld puck, which I will try next.CT4, CT4-V or CT4-B Blackwing Lift Points

From the CT4 Service Manual that was shown by @Dirkbg above, I tested those locations using a low profile jack + three hockey pucks stacked (each 3"x1" WxH) to lift the car for some wheel detailing work. I used the pucks as that were the only pads immediately available for me but a better option would be the Quickjack Pinch-Weld Blocks that @Jameson's Viggen noted he purchased for lifting his 4BW. I measured the front molding opening at the pinch weld and these Blocks would fit nicely.

For the FRONT, I used the pinch weld as noted in the instructions: "In the front location, place the lift pads on the rocker outer panel weld flange."

For the REAR, I used the rear cradle brace per instructions, diagram, and pics.

View attachment 18078

View attachment 18079

View attachment 18080

View attachment 18081

View attachment 18082

I used a 6000ELX to change my oil and it was a giant pain in the A**. The car is so low that it’s difficult to reach between the quickjack and bottom of the car to align the lifting blocks.

MatthewAMEL

Seasoned Member

I have the -6000 also. Sold my -5000 because it was too short.I could not get that quickjack pinch weld block to fit on the rear jacking point of the CT-4 BW. They also make a pinch weld puck, which I will try next.

I used a 6000ELX to change my oil and it was a giant pain in the A**. The car is so low that it’s difficult to reach between the quickjack and bottom of the car to align the lifting blocks.

I didn't have any issues with spacing. But I don't have CF2 and perhaps the BW5 is slightly taller?

Similar threads

- Replies

- 6

- Views

- 1K